15n hardness test|rockwell superficial 15n hardness : service In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial . Intervalo real é a quantidade de concursos que fizeram parte do referido ciclo. Intervalo médio é a média dos intervalos de todos os ciclos inversos fechados. Ciclos inversos em sorteios da Lotofácil - Veja também frequências, atrasos, sequências, repetições, distribuições, somatórias, duplas, trincas, ciclos.

{plog:ftitle_list}

4 semanas atrás. em. 28/01/2024. Portal de Pinhal. Confira os ganhadores do JF da Sorte! No domingo, 28 de janeiro de 2024, serão divulgados os ganhadores do sorteio .

rockwell superficial 15n hardness

HR-15N. The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen hardness. The harder the material, the higher the HR reading. The most common is the static load indentation hardness test, such as Brinell Hardness (HB), Rockwell Hardness (HRA, HRB, HRC), and Vickers Hardness (HV). These hardness values indicate the ability of a .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial .

scratch test cost

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of theAC Adapter Hardness test Block 30 HRC Hardness test Block 30 HRC Users Manual Hardness test Block 90 HRBW Hardness test Block 90 HRBW . Rockwell Superficial hardness 15N HR15N Conical diamond 29.42N (3kgf) Coverage 147.1N (15kgf) 70-94HR15N 30N HR30N 294.2N (30kgf) 42-86HR30N 45N HR45N 441.3N (45kgf) 20-77HR45NHome "15N" Scale Rockwell Hardness Test Block. Click or scroll to zoom Tap or pinch to zoom "15N" Scale Rockwell Hardness Test Block 9.00 SKU 20545 HR15N. Quantity Quantity. Add to cart Available in N-Diamond 15Kg (Round) HR15Ns from 72 to 91.5. Manufactured from the highest quality steel with a special heat treat and cold treat process .HARDNESS CONVERSION CHART HRA HRB HRC HRD HRE HRF 15-N 30-N 45-N 30-T 3000 kg 500 kg Rockwell Rockwell Superficial Brinell Vickers Shore 61 98 21 40.9 --- --- 69.9 42.3 20.7 81 228 189 243 35

Shop Hardness Test Blocks - HR15N Standard from YAMAMOTOKAGAKU (HR15N-87). MISUMI USA has all of your Hardness Test Blocks needs covered, with over 3.8M high quality products and 80 sextillion configurable parts available with fast shipping and low pricing. Rockwell Certified Hardness Test Block. "15N" Scale. Manufactured from the highest quality steel with a special heat treat and cold treat process which insures maximum consistency and repeatability. Accuracy exceeds ASTM E10, .

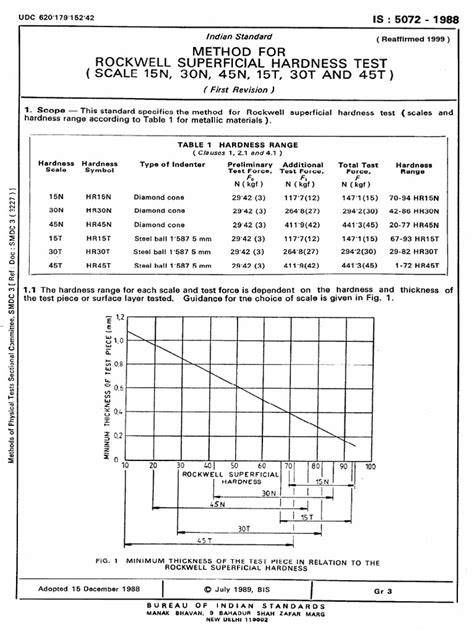

The Rockwell Superficial hardness test method consists of indenting the test material with a diamond cone (N scale) or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load F0 (Fig. 1A) usually 3 kgf. When equilibrium has been reached, an indicating device that follows the movements of the .Metallic materials — Rockwell hardness test — Part 1: Test method. Skip to main content. Applications; OBP; English. español; français; . 15N, 30N, 45N, 15T, 30T, and 45T for metallic materials and is applicable to stationary and portable hardness testing machines.

The Superficial Rockwell hardness test method consists of indenting the test material with a diamond cone (N scale) . 15N: 120o Diamond cone: 117.72: 100: Similar to C scale, but for thin materials: 30N: 120o Diamond cone: 264.87: 100: Same as 15N: 45N: 120o Diamond cone: 412: 100: Same as 15N: 15T:Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . Rockwell Superficial hardness 15N HR15N Conical diamond 29.42N (3kgf) Coverage 147.1N (15kgf) 70-94HR15N 30N HR30N 294.2N (30kgf) 42-86HR30N 45N HR45N 441.3N (45kgf) 20-77HR45N 15T HR15T A scale indicating the hardness of materials, first used in 1919, when it was invented by Stanley P. Rockwell.The measurement has no units. The symbol is HR followed by a letter indicating one of a number of possible scales, described in the table below.

HR15N to HRC Conversion HR15N to HRC Conversion Calculator Enter HR15N Hardness: Convert FAQs GEGCalculatorsGEG Calculators is a comprehensive online platform that offers a wide range of calculators to cater to various needs. With over 300 calculators covering finance, health, science, mathematics, and more, GEG Calculators provides users .HR-15N : The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen hardness. The harder the material, the higher the HR reading. In the test, a minor load (10 kgf) is first applied, and the test dial (measuring the indention .

15N Scale Rockwell Test Block - 88 RangeEach test block has been calibrated on a hardness tester whose accuracy has been verified using N.I.S.T. traceable load and depth measuring devices. The test blocks are made from only the highest quality material to ensure complete uniformity and repeatability. They are hand lapp

Test Cycle: This SRM unit has been certified by performing Rockwell 15N scale hardness tests using a specific test cycle. The HR15N test cycle may be characterized by specifying four test cycle parameters that have been determined to have a significant influence on the measurement results. The four parameters are: (1) preliminary

Rockwell Certified Hardness Test Block. "15N" Scale. Manufactured from the highest quality steel with a special heat treat and cold treat process which insures maximum consistency and repeatability. Accuracy exceeds ASTM E10, E18, E92 and E384 standards.An example would be converting HV/10 or HR-15N value on a thin coating to the HRC equivalent. Links To: Hardness Testing Rockwell Hardness Test Rockwell Superficial Hardness Test Brinell Hardness Test Vickers Hardness Test Microhardness Test Mohs Hardness Test Scleroscope and other hardness testing methods Hardness Conversion Tables and Charts:Rockwell: Rockwell Superficial: Brinell: Vickers. Shore : A: B: C: D: E: F: 15-N: 30-N: 45-N: 30-T: 3000 kg: 500 kg: 136 . Approx Tensile Strength (psi) 60kg Brale .The regular Rockwell hardness testing scales use heavier force (load) levels. For these scales, the preliminary force (minor load) level is 10 kgf and the standard total force (load) levels may be 60 kgf, 100 kgf or 150 kgf. The superficial Rockwell hardness testing scales use lighter force (load) levels, typically for use on thinner materials.

The standardized test blocks are calibrated in accordance with ASTM E18 section Annex A4 using NIST Rockwell standard reference materials (SRM) 2810, 2811, and 2812. All other scales are traceable to manufacturers hardness levels through laboratory standardizing machines.The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen hardness. The harder the material, the higher the HR reading. . HR-15N << Rockwell Superficial 15N : 69~94 HR-30N << Rockwell Superficial 30N : 41~85 HR-30T : 66 . The test procedure for the Rockwell hardness test is covered in the standard document ISO 6508 for metallic materials and ISO 2039-2 for plastics. The overall procedure is similar to other indentation tests. The indenter is pressed into the material, loaded for a time interval (dwell time), and unloaded. .

Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table . Brinell Hardness: Rockwell Hardness: Tensile Strength (Approximate) Psi: Tungsten Carbide Ball 3000 KG: A Scale 60KG: B Scale 100KG: C Scale 150KG-85.6-68.0--85.3-67.5--85.0-67.0-767: 84.7-66.4-757: 84.4-65.9-745: 84.1-65.3-733: 83.8-64.7-722: 83 . Rockwell Certified Hardness Test Block."15N" Scale. Manufactured from the highest quality steel with a special heat treat and cold treat process which insur maximum consistency and repeatability. Accuracy exceeds ASTM E10, E18, E92 and E384 standards.

Rockwell Certified Hardness Test Block. "15N" Scale. Manufactured from the highest quality steel with a special heat treat and cold treat process which insures maximum consistency and repeatability. Accuracy exceeds ASTM E10, E18, E92 and E384 standards.

scratch test cells

14 de ago. de 2020 · 1.5K. 36K views 2 years ago. Neste vídeo, você vai entender como funcionam os Ciclos dos Números da Lotofácil, e também vai conferir algumas dicas, e como estas informações .

15n hardness test|rockwell superficial 15n hardness